Engineered for strength, safety and dependability to meet the requirements of today’s bulk industry needs.

Phelps Truck Dumper Features

Yokes (Extended Arm Dumpers)

Wheel Chocks

36 ̊ and 45 ̊ dumpers are available with hydraulically operated wheel chocks. The trailer tires rest against the raised chock to keep the truck

on the platform during the dumping operation. These chocks are carefully engineered and heavily constructed to retain the load against them and to compensate for any misalignment of the truck on the platform.

Wheel Guides

Wheel Guides are an integral component to every Phelps truck dumper which is used to safely guide the truck on and off of the dumper. The wheel guides are formed from steel and fully welded to the driving surface of the dumper.

MODELS

Reclaim Conveyors

Cylinders

Backstops

The Deck

Dust Abatement

Phelps offers options for dust abatement and collection on our extended arm truck dumpers and above-grade hoppers. Contact Phelps for more information.

Mounting Options

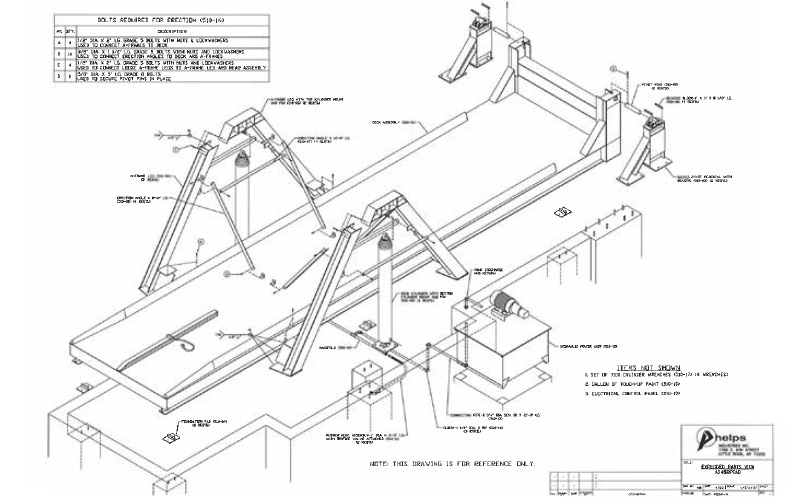

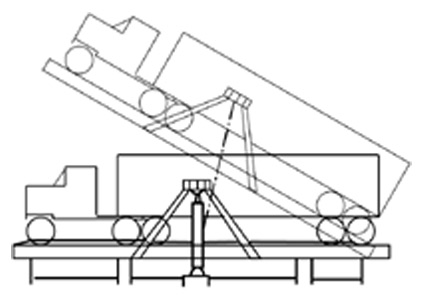

“A-Frame” Cylinder Mounting (Pit-less)

The “A-Frame” model is designed and built for above ground installation. This type of truck dumper is very desirable in areas with a high-water table or locations where the soil does not allow the digging of a cylinder pit. The “A-Frame” arrangement allows for easy access to the deck cylinders.

The “A-Frame” model is designed and built for above ground installation. This type of truck dumper is very desirable in areas with a high-water table or locations where the soil does not allow the digging of a cylinder pit. The “A-Frame” arrangement allows for easy access to the deck cylinders.

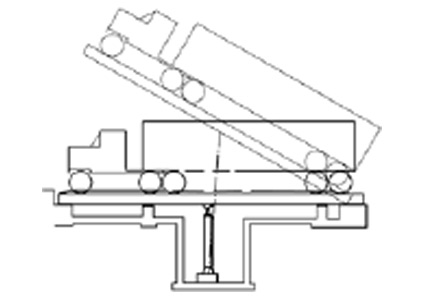

Under Deck Cylinder Mounting (Pit Type)

This model is sometimes preferred when the water table permits, and the cost of excavating a cylinder pit is not prohibitive. It leaves clean lines (flush with the ground) when in the down position.

This model is sometimes preferred when the water table permits, and the cost of excavating a cylinder pit is not prohibitive. It leaves clean lines (flush with the ground) when in the down position.